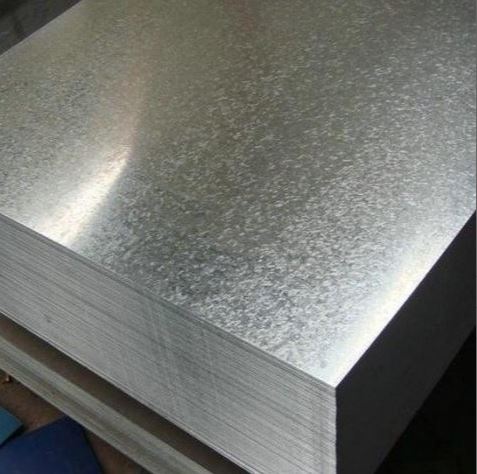

We can find galvanized materials everywhere, even if we don’t see it at first glance. Galvanized iron sheets are an essential part of our lives, as they are used in construction, transport and any other sectors where preventing corrosion is a vital factor. This is why companies such as Harwal Group, the best building materials manufacturers, make this kind of material which can be acquired in this link.

Galvanizing is a technique that has been used to protect iron and steel from corrosion for over 250 years. Corrosion is caused by an inherent tendency of metals when subjected to air and moisture, which tend to return to their original earth form, usually a mineral state. They do so through a chemical or electrochemical reaction with the environment. Galvanizing consists of immersing steel parts in molten zinc to protect them from corrosion and enhance their mechanical strength to shocks and abrasion. The most common galvanizing consists of depositing a layer of zinc (Zn) on iron (Fe). The purpose of such a process is to help resist oxidation and corrosion that can be caused by humidity and environmental contamination of the coated material.

The galvanizing process can be by hot-dip, immersion or fire. There are other galvanizing techniques such as ‘continuous galvanizing’ or ‘electrogalvanizing’ but the hot dip method is the most widespread thanks to its results. It consists of introducing pieces of iron in molten zinc at a temperature of approximately 450°C until a coating of 7-42 microns (low coating, regulated by UNE EN ISO 10346) or 45-200 microns (high durability, regulated by UNE EN ISO 1461) is achieved. By combining zinc and iron a layer which has a great adherence, is very resistant to shocks and has great hardness is created. It especially indicated to be used outdoors and in humid or corrosive environments.

How are galvanized iron sheets made?

First of all, the iron parts must be processed individually and with the desired size, be it nails, sheets, tubes or any other type of element. Next, some of the aforementioned galvanizing techniques -such as immersion galvanization- is applied.

While submerged in the boiler, the zinc reacts with the iron in the steel to form a series of intermetallic alloy layers of zinc and iron metallurgically bonded, commonly crowned by a layer of pure impact-resistant zinc darmowa kasa za rejestrację bez depozytu. The metallurgical reaction ends when the molten zinc bubble in the boiler stops. At this point, the galvanizing is complete and the steel is removed from the kettle to cool. Once the part coating is complete, it is slowly removed from the galvanizing bath, and excess zinc is removed by drainage, vibration and/or centrifugation.

The metallurgical reaction continues after the materials are removed from the bath, as long as they remain close to the bath temperature. Galvanized articles are cooled by immersion in a passivation solution or water or by being left outdoors.

Advantages of galvanized iron sheets

Products made of galvanized steel offer the great advantage of requiring no maintenance. Some galvanized products are: sheets, nails, keys, tubes, poles, wires, etc. The main raw material for galvanizing is zinc.

Longer duration

Galvanized structures have a long life of between 30 and 60 years, of course, this depends on the degree of exposure of the steel to corrosive agents.

Versatility and reliability

Hot-dip galvanizing serves to protect all kinds of steel parts and articles, so galvanization can protect all types of steel parts of different sizes and shapes. Plus, hot-dip galvanized coatings are one of the few steel protection systems that are perfectly specified by national and international standards, which guarantees duration and reliability

Cost reduction and low maintenance

Its initial cost is reasonable due to the fact that it has a high duration, therefore it is economic in the constructions. Thanks to galvanizing there is no longer any need for painting or maintenance.

Nice aesthetics and easy to paint

Its shiny, modern look makes it attractive to consumers, but it can be also decorated as desired since it is very easy to paint. Galvanised steel is usually painted for signalling, camouflage etc. They also do so to increase the duration of protection in aggressive environments. It is important to know that galvanized steel has adhesion problems and must be clean, dry and free of any contamination, including zinc salts and any chromate solution* before painting. This can be achieved by using a wash with a biodegradable detergent or with a metal degreaser and conditioner.

Triple protection

Galvanized materials provides protection in three different levels: Hard metal barrier, electrochemical protection and self-healing protection. As an additional advantage, in addition to being durable and resilient, galvanized steel can be recycled several times, making it widely used for a wide variety of purposes.

Bitcoin

Bitcoin  Ethereum

Ethereum  Tether

Tether  XRP

XRP  Solana

Solana  USDC

USDC  Cardano

Cardano  TRON

TRON  Lido Staked Ether

Lido Staked Ether  Avalanche

Avalanche  Toncoin

Toncoin