Background

The material slip additives are utilized for the reduction of friction among films as well as transforming the equipment that helps in improving the movement between the operations of downstream packaging and the extrusion lines. It helps in improving the process and the end applications. Commercially vital slips can be easily available in the chemical family amides and are known as “Oleamide or fast bloom” and “Erucamide or slow bloom”. The efficiency of slip additives is distinguished by the COF factor or “coefficient of friction” (Peloso et al., 1998). COF is the ratio of the required force to slide a layer of film over another layer to the exerted gravimetric force on it. The most general slip agent utilized for Polyolefin are fatty acid, long-chain including amides from the single unsaturated C-18 through C-22 single unsaturated.

Slip additives are very effective since they have the natural tendency of surface bloom. Various slip agents possess various rates of surface bloom as well as COF reduction. The shorter length chain of the amides rapidly tends to bloom to the surface; however, thermal stability is less compared to the high chain length. The amides with high chain length have a slower rate of bloom with high thermal constancy (Dulal et al., 2018). On the basis of carrier resin, the internal slip additives market has been separated into four areas including LDPE, LLDPE, PP and HDPE.

In general, slip additives are the products that are added to the polymers for controlling friction. They are directly added, during the procedure of extrusion into the polymer. The major utilization of this product is to improve the polymer processing of plastic products. Amides with fatty acids consisting of primary as well as secondary amides are the common slip additives. The major properties of the slip additives include that the relocation of the slip additives takes time as well as the ultimate COF might not be attained until 7-10 days after the extrusion.

How do Slip additives works?

Slip additives are the products that help in reducing the friction between the layers of films. When these additives are added to the polymer, it controls the friction and provides good quality end products to the consumers. These are added in the making of the polymer and during the procedure, the additives migrate to the polymer’s surface. In the final stage, a lubricating coat forms over the plastic which decrease the COF (Dulal et al., 2017) or the coefficient of friction. Utilizing this additive, plastic parts can able to run smoothly over another surface with minimum damage. For manufacturing the polyolefin, these additives are extensively used.

Different types of Slip additives

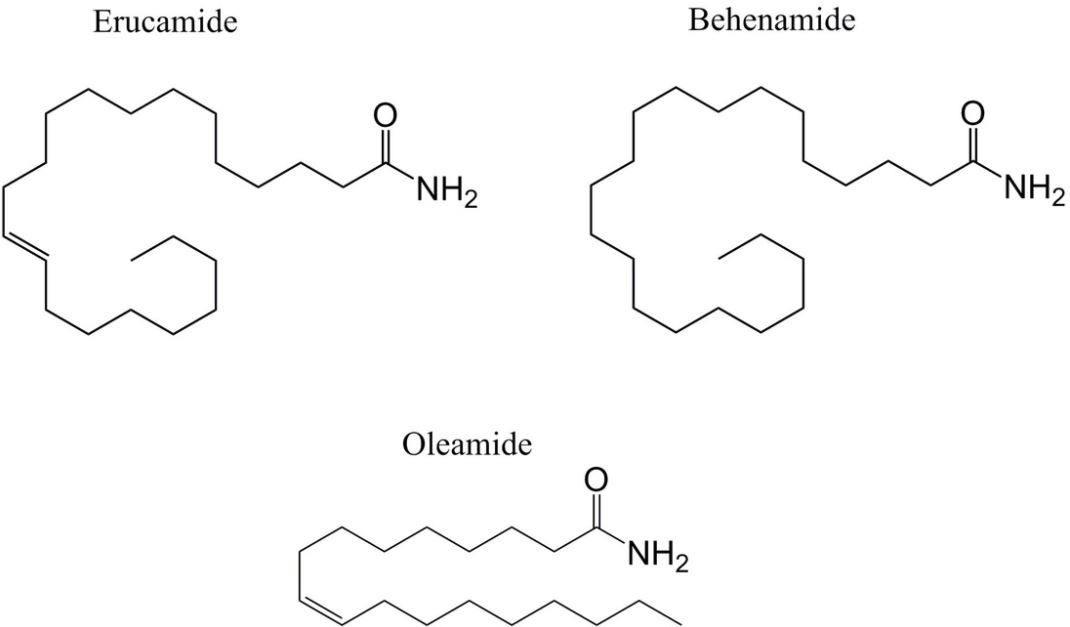

There are various kinds of slip additives are found, however, the most common slip additives utilized for making polyolefin are the fatty, long-chain amides that are thermally more stable. Based on the types, the slip additives market has been classified into three areas

- Fatty Amides

- Erucamide

- Oleamide

- Stearamide

- Behenamide

- Secondary Amides

- Waxes as well as Polysiloxanes

- Ester and salts

Bio-based slip additives are also available which are plant-based products and act as an alternative to Erucamide. These natural additives are much efficient for the reduction of COF. Bio-based slip additives are thermally stable as well as less volatile during the polymer making process.

Why it is important to have efficient slip additives?

Polyester like PET as well as PLA is broadly utilized in the food packaging sector. However, the difficult section of processing as well as handling PET is its tough surface bond. Thus, efficient Slip additives are needed for the reduction of the coefficient of friction from the polymer’s surface throughout processing, as well as handling and application of it. This allows improved processibility and helps in the reduction of the surface defect risks.

Application

- The major application of Slip additives is usually in the plastic making sector. This sector is constantly growing in recent years and especially the food packaging sector. The utilization of slip additives for making polymer processing smooth has been the recent trend in the plastic industry. The packaging sector has utilised this product for avoiding friction between two layers of film (Dhanvijay et al., 2014).

- The implementation of slip additives is adjusted based on the kind of polymer as well as the thickness of the layer for the end products.

- The utilization of this product is consistently augmenting in the various sectors as it gives chances to manufacture suitable quality films.

- Bio-based slip additives are quite effective for the plastic industry as well as the environment.

FAQs

Q1. What are Slip Additives?

Ans. Slip additives are the products that help in reducing the friction between the layers of films. When these additives are added to the polymer, it controls the friction and provides good quality end products to the consumers.

Q2. How do Slip Additives work?

Ans. Slip Additives are added to the polymer manufacturing process according to the quality and the thickness of the films. It reduces the friction between two layers and makes the process of making plastic products much smoother. In the final stage, a lubricating coat forms over the plastic which decrease the COF or the coefficient of friction.

Q3. What are the types of Slip Additives?

Ans. The Slip Additives are mainly found in three major forms. Fatty Amides, Waxes as well as salts based. Bio-based slip additives are also available which are plant-based products and act as an alternative to Erucamide. The fatty amides include Erucamide, Oleamide, Stearamide, Behenamide as well as Secondary Amides.

Q4. Which regions dominated the slip additive market in recent years?

Ans. The international slip additive market has been classified across five regions

- Asia-Pacific

- North America

- Europe

- Latin America

- Middle East

The Asia Pacific has dominated the market in recent years as the growth of the plastic industry can be observed in this region constantly whereas the region of North America holds the second position because of the widespread utilization in the food and beverage packaging sector. According to the statistics made in 2019, the other three regions are not consistent as with the above two mentioned regions.

Bitcoin

Bitcoin  Ethereum

Ethereum  Tether

Tether  XRP

XRP  Solana

Solana  USDC

USDC  TRON

TRON  Cardano

Cardano  Lido Staked Ether

Lido Staked Ether  Avalanche

Avalanche  Toncoin

Toncoin