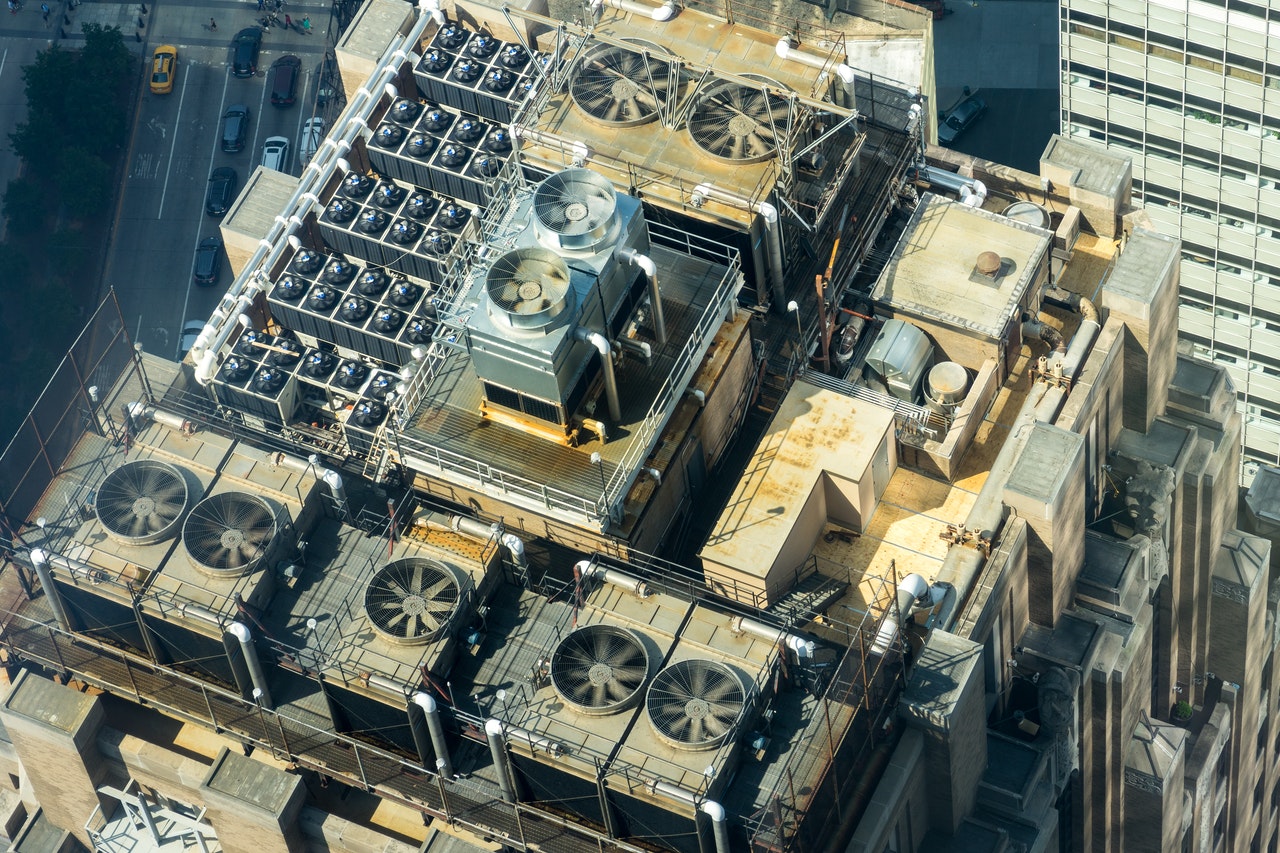

Challenging environments with a high risk of a catastrophic event breaking out call for specialist HVAC equipment. This is not just to ensure that operations can be done but to keep employees (and in some cases, the public) safe from harm.

Industrial companies operating in these challenging environments — oil, gas and food sectors for instance — have added responsibilities. These industrial factories tend to be hotter than the average workplace, which affects the staff and can cause a higher risk of an explosive atmosphere. This is where fumes, gases or tiny particles of combustible dust fill the air from raw materials. All it takes is a small ignition source, such as welding sparks, to set off an explosion.

This is why hazardous air conditioning units are vital within these settings.

What Are the Benefits of Hazardous Air-Conditioning Units?

Conventional air conditioning units are not designed to cope with industrial environments, posing a more significant risk of an explosion. Hazardous air conditioning units are specialised so that they’re hermetically sealed, keeping everything in. More importantly, they won’t overheat and are safer for people and facilities — they’re designed to be ultra-reliable, operating in the most challenging environments without breaking down.

ATEX-Approved Air Conditioning Units

This brings us to ATEX-approved air conditioning units. ATEX is the collective name given to the two European Directives for controlling explosive atmospheres. These directives make it mandatory for manufacturers of various equipment to design their tools to a certain standard — and cover their use on the factory floor and elsewhere. The directives cover a large range of equipment, potentially including equipment used on fixed offshore platforms, in petrochemical plants, mines, flour mills and other areas where a potentially explosive atmosphere may be present.

ATEX-approved air-conditioning units, such as market-leader Friedrich, are extremely efficient and designed to function in areas where flammable liquids or gases are exposed and will not rise above 135C, despite the temperatures indoors or outdoors. The unit’s fan motor is sealed, and it has corrosion resistance and other features to help ensure it won’t break down and, with regular servicing, will keep ongoing.

Another benefit to providing ventilation for all employees is limiting the risk of heat stress. The Health, Safety & Welfare regulations place a legal obligation on employers to ensure that ‘reasonable’ temperatures are maintained within the workplace.

Examples of areas where it’s vital to have cool air delivered by a sealed air conditioning unit:

- Oil sectors

- Food sectors

- Factories that use dangerous chemicals

- Petrochemical facilities

- Hazardous materials storage.

Installing specialised air-conditioning units will allow your employees to carry out their tasks safely, reassuring them that they are safe from danger. For managers, investing in hazardous air conditioning units means complying with health and safety laws, as well as the reassurance that they are helping to protect their employees and members of the public.

Bitcoin

Bitcoin  Ethereum

Ethereum  Tether

Tether  XRP

XRP  Solana

Solana  USDC

USDC  TRON

TRON  Cardano

Cardano  Lido Staked Ether

Lido Staked Ether  Avalanche

Avalanche  Toncoin

Toncoin