When searching for a credible rotary valve manufacturer, there are several key factors to consider. Understanding these factors can help you make an informed decision. This article will guide you through the process.

Finding a trustworthy manufacturer for your rotary valve needs is crucial for ensuring high-quality products and services. Given the myriad of manufacturers available, it’s essential to know what to look for and why these elements matter. This guide will provide you with the necessary steps to identify a reputable supplier.

Identifying Quality Standards

The first step in finding a reliable rotary valve manufacturer is to assess their quality standards. Look for manufacturers who adhere to international standards such as ISO 9001, which ensures that they follow stringent quality management systems. This certification is a testament to their commitment to producing high-quality products. Additionally, check if they have industry-specific certifications that indicate their expertise in manufacturing rotary valves.

Another crucial aspect is customer reviews and testimonials. These can offer valuable insights into the manufacturer’s reliability and product quality. Seek out feedback from previous clients to understand their experiences. For instance, you might find a review stating that a particular manufacturer consistently delivers high-performing rotary valves, which is an excellent indicator of reliability.

It’s also important to investigate the manufacturer’s quality control processes. A reliable rotary valve manufacturer should have robust quality assurance measures in place, including rigorous testing procedures for each product. This might involve pressure testing, material analysis, and performance simulations. Ask about their quality control protocols and whether they provide detailed documentation of these tests with each product. A manufacturer who can demonstrate a consistently low defect rate and a commitment to continuous improvement in their manufacturing processes is likely to be a dependable choice.

Evaluating Technical Expertise

A manufacturer’s technical expertise is another vital factor to consider. Ensure that the manufacturer has a team of experienced engineers who can provide technical support and guidance throughout the purchasing process. Their ability to offer custom solutions tailored to your specific needs indicates their proficiency in the field.

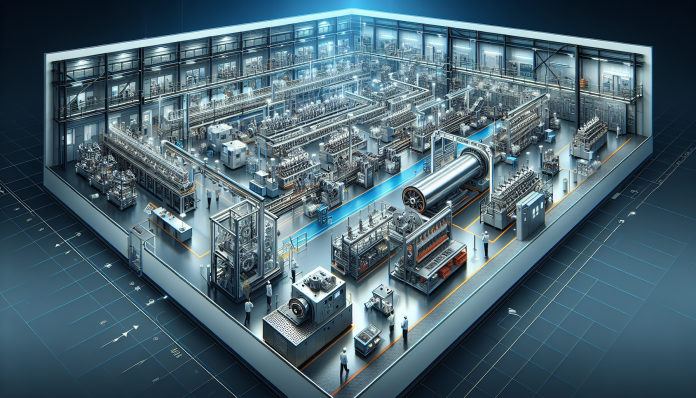

Additionally, evaluate their production capabilities and facilities. A manufacturer with advanced machinery and technology is more likely to produce high-precision components, which are essential for the efficient functioning of your equipment.

Assessing Customer Service

Excellent customer service is a hallmark of a reliable manufacturer. Pay attention to how promptly and effectively they respond to your inquiries. A responsive and knowledgeable customer service team can significantly enhance your purchasing experience by providing timely assistance and addressing any concerns you may have.

Moreover, consider their after-sales support services. A manufacturer that offers comprehensive after-sales support demonstrates their commitment to customer satisfaction. This includes providing maintenance services, spare parts availability, and technical assistance post-purchase.

Considering Price and Delivery Time

While price should not be the sole determining factor, it is still an important consideration when choosing a manufacturer. Compare prices from different manufacturers to ensure you are getting a fair deal without compromising on quality. Be wary of unusually low prices, as they may indicate subpar products or services.

Lastly, take note of the manufacturer’s delivery times. Timely delivery is crucial for maintaining your production schedule and avoiding unnecessary delays. A reliable manufacturer will provide clear timelines and stick to them, ensuring that your equipment arrives when needed.

Bitcoin

Bitcoin  Ethereum

Ethereum  Tether

Tether  XRP

XRP  USDC

USDC  TRON

TRON  Lido Staked Ether

Lido Staked Ether  Cardano

Cardano  Avalanche

Avalanche  Toncoin

Toncoin  Wrapped SOL

Wrapped SOL