Electroplating for demanding businesses

With copper or aluminium electroplating, a wide range of technological advancements would not be possible to achieve. Let’s have a look at why this particular process has such a big impact on our civilisation. Let’s see how modern approach makes it even bigger.

The benefits of electroplating

The electroplating plays an important role in the economy. It provides a range of high-quality, durable coatings that protect and enhance the longevity and functionality of different metal components. Better corrosion resistance, for example, improves outdoor installations of any sort. Enhanced conductivity, on the other hand, ensures smooth and efficient current flows, resulting in better performance of electronic devices.

That’s why electroplating is a game-changing solution for multiple industries. From telecommunication to aerospace, medical devices, and even jewellery. In the automotive sector alone, electroplating is widely used for both decorative and functional purposes. Tin plating, a silvery-white coating, is used to protect parts from rust and other forms of corrosion, while electroless nickel plating is used to increase the wear resistance and hardness of engine components. The use of electroplating in the automotive industry ensures that vehicles are both visually appealing and functionally safe.

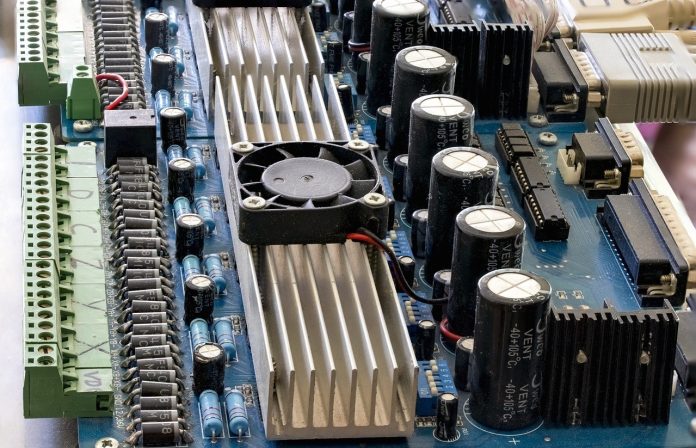

In the electronics industry, electroplating is used for the production of integrated circuits and printed boards, as well as the creation of connectors, terminals, and pins. The use of real silver plating for electrical contacts is particularly popular, as it has a wide operating temperature range. It also offers good corrosion protection with exceptional conductivity. The application of electroplating in electronics ensures reliable performance of any device, thus increasing its efficiency.

In medical devices, electroplating is used to produce implantable components, such as stents, screws, plates, and joints. These coatings must be biocompatible and able to withstand the corrosive properties of body fluids to avoid adverse effects on the patient’s health. Electroplating is the preferred method of surface modification in the medical field because it optimises the performance of the medical device while minimising potential harm to the patient.

Automation of electroplating and quality control

The above goes side by side with modern production standards. That means automotive processes, which ensure that every component has exactly the same layer of coating as thousands of its counterparts on the production line. Automation greatly speeds up industrial processes. In addition, it provides means for better quality. The error margin is basically minimal, although technological tests are still required. But they are also conducted via sophisticated tools in the hands of highly qualified personnel. As a result, the quality level can be more exceptional than ever.

The highest quality of electroplating, however, demands specialised facilities. Only fully modernised factories are capable of delivering products in line with top requirements. Automated machines, software, and people who control the whole process without delays—they are a must. The ability to offer a range of coating types and thicknesses is also appreciated due to various product specifications. This way, a single service provider can handle complicated orders in just one location. Are you interested in more details? Please visit https://www.electriscoatings.com/en/services/electroplating-coatings.

Bitcoin

Bitcoin  Ethereum

Ethereum  Tether

Tether  XRP

XRP  Solana

Solana  USDC

USDC  Cardano

Cardano  TRON

TRON  Lido Staked Ether

Lido Staked Ether  Avalanche

Avalanche  Toncoin

Toncoin