The Fast Moving Consumer Goods industry includes processed foods, beverages, cosmetics, toiletries, cleaning products, pharmaceuticals, and plenty more. Given that FMCG covers such a broad range of consumer products, it is a highly competitive industry that is worth £134 billion annually in the UK alone.

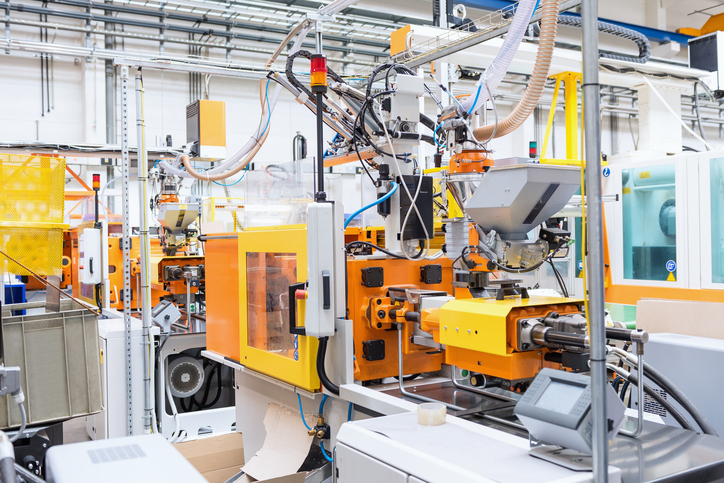

There will always be a high demand for FMCG goods among consumers. Fortunately, modern-day robotics and automation systems are here to stay and they should be embraced. Robotics and automation are transformative manufacturing solutions that can significantly raise the productivity levels of companies producing fast-moving consumer goods products.

Heightened speed and efficiency

One of the main benefits of using integrated robotics and automation for product manufacturing is its impressive speed and effortless efficiency. The human workforce working in manufacturing plant settings will always be vulnerable to injuries, and accidents, needing extended time off work due to ill health, and getting tired from repetitive tasks.

Robotic machinery on the other hand can work around the clock relentlessly and perform repetitive tasks at ease. To keep productivity levels and profits high in an FMCG manufacturing environment, the name of the game is minimising downtime, and robotics and automation machinery are ideal for ensuring just that.

You will notice speed and efficiency improvements in no time after adopting robotics and automation systems.

Enhanced manufacturing safety

Fast-moving consumer goods manufacturers using complicated technical processes for heavy machinery at a high speed can come with their fair share of hazards and risks. Thankfully, automated machine technology has its bonuses, and using robots specially designed to carry out high-risk production activities can go a long way in improving safety in fast-moving consumer goods manufacturing.

Adaptability

When producing FMCG products en masse, you need manufacturing machinery that will be up to the task of meeting the ever-changing consumer demands and seasonal fluctuations. For instance, consumers will tend to buy more food and beverage products around the Christmas period of the year, and manufacturers need to have tools on right tools on deck that meet such spikes in demand.

A cost-effective manufacturing solution

Since robots can work without needing breaks and require next to no maintenance and upkeep, they are undoubtedly a cost-saving solution, despite the early investment that goes into them. In addition, manufacturers will find that well-built robotic tools have a lengthy lifespan which can lead to further savings.

Intricacy and precision

Producing lots of batches of faulty products will hit your bottom line as a manufacturer. Luckily, modern robotics are fitted with well-designed sensors, and this means they can perform intricate tasks with impressive precision. Want to ensure quality requirements are met during the production process with few bumps in the road? Robotics and automation systems could be a perfect option.

Are you looking for efficiency, speed, and precision, as well as making cost savings in your FMCG manufacturing processes? By far the best long-term solution is to start using integrated automated technology as soon as possible.

Bitcoin

Bitcoin  Ethereum

Ethereum  Tether

Tether  XRP

XRP  Solana

Solana  USDC

USDC  TRON

TRON  Cardano

Cardano  Lido Staked Ether

Lido Staked Ether  Avalanche

Avalanche  Toncoin

Toncoin