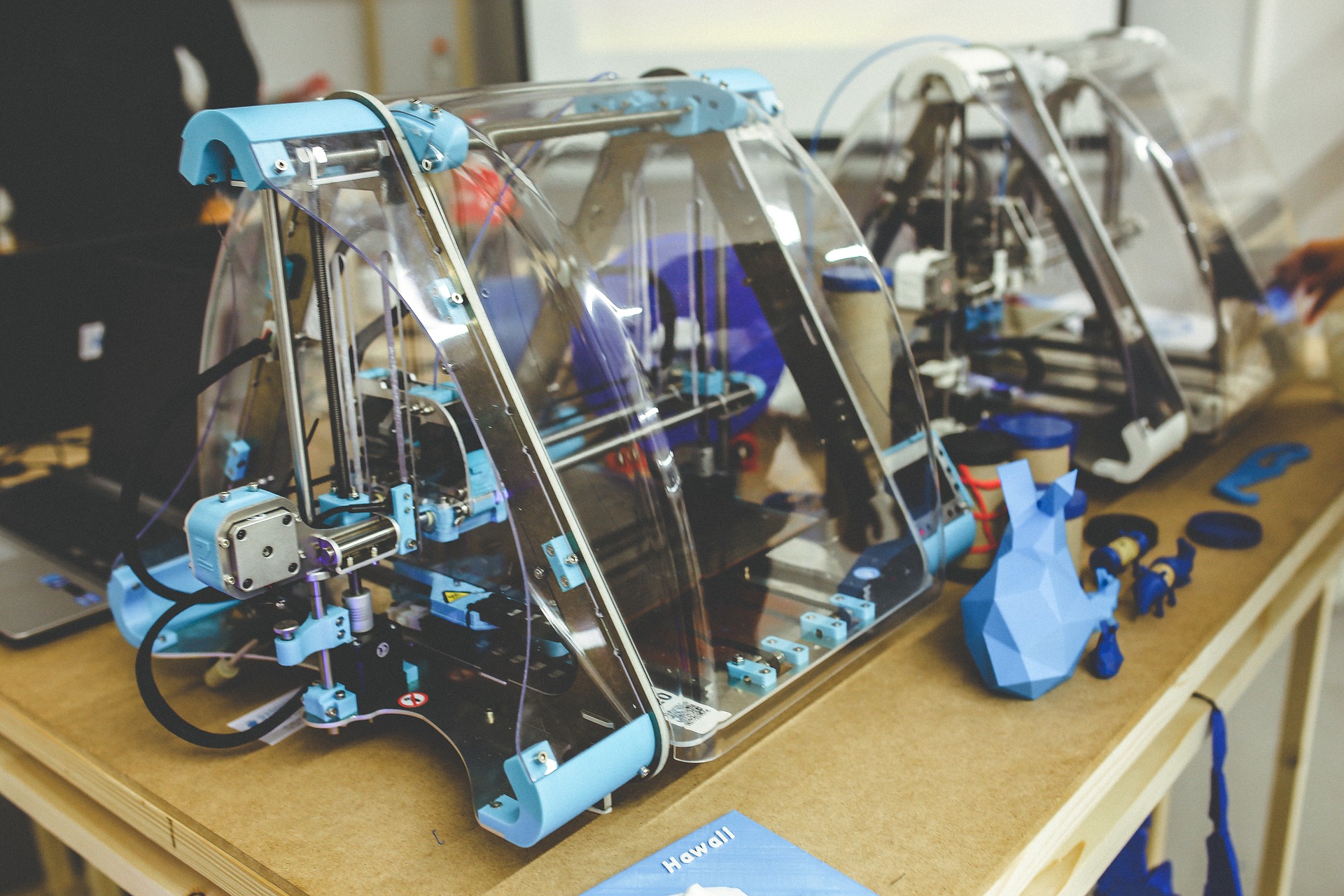

The 3D Printing technology comes in handy in most industrial manufacturing processes. Whether it’s on the internet and the ground, you will find details of 3D printing and how companies invest in it because of its several advantages. From the little things such as toys and figurines to the industrially printed bridges, propellers, and rockets, 3D has become a game-changer in the technological and industrial world. Here are some of its advantages.

Enhances Faster Production

To companies that have invested in 3D printing, most processes that lead to a complete production have become unnecessary or redundant. With this type of manufacturing, a program gets installed into the 3D printer and then fed with the right materials to produce the item. You only need a small workforce or another machine to assemble and put the last touches on the product. Before then, it could take tens of processes, human labour, and machines to develop a single product. Besides making things produced on time, companies are now producing items where they are needed. NASA is preparing a major milestone to print its items on the moon, making astronauts have ready tools when they need them. It is also helping doctors in remote areas come up with prosthetic limbs and implants in real-time, on location.

Produces less waste

In most manufacturing processes, the raw material is often more than what is required for the product. Production starts with the larger quantity as it molds the product, leaving the excess material behind. While this material is later reused in the next process, its time consuming and not all can be reused. According to specialists of 3d printers from Konica Minolta, most 3D processes layer down the raw materials, reducing their usage. There is less or no trimming of the finished product, which reduces wastage. It also prevents transferring raw materials to the production site, reducing costs, damages, and other environmental expenses.

More Product designs

Before the arrival of 3D, most companies stuck on one design because it took time to create new ones and adjust machines. With 3D printing, manufacturers now have the freedom of producing as many designs and structures as possible, depending on their products. 3D uses thinner layers of materials and mathematical methods that engineers couldn’t apply to production machines. Products are now customisable, depending on the user, making it possible to produce organ implants that perfectly fit patients, Intrauterine Devices for women with larger or smaller uteruses, and other customised items in the medical and other fields.

Reduces Production Cost

Before introducing the 3D printing service, investors had to provide huge funding to purchase several machines and equipment to produce a single product. It also involved getting enough labour force, materials, and transit for each process, making the total production expensive. Things have changed. Companies can now produce several complex items and parts using the printer and fewer machines to finalise the product. It also requires fewer workers, less power, and less working space. There is also reduced transport for raw materials and finished products since production can be done remotely.

There are several benefits for companies indulging in 3D printing. The above are only a few but greatly highlight what this process can do. With it evolving, we will continue witnessing new product designs and more companies since production will be affordable, fast, and flawless.

Bitcoin

Bitcoin  Ethereum

Ethereum  Tether

Tether  XRP

XRP  Solana

Solana  USDC

USDC  TRON

TRON  Cardano

Cardano  Lido Staked Ether

Lido Staked Ether  Avalanche

Avalanche  Toncoin

Toncoin